Overview

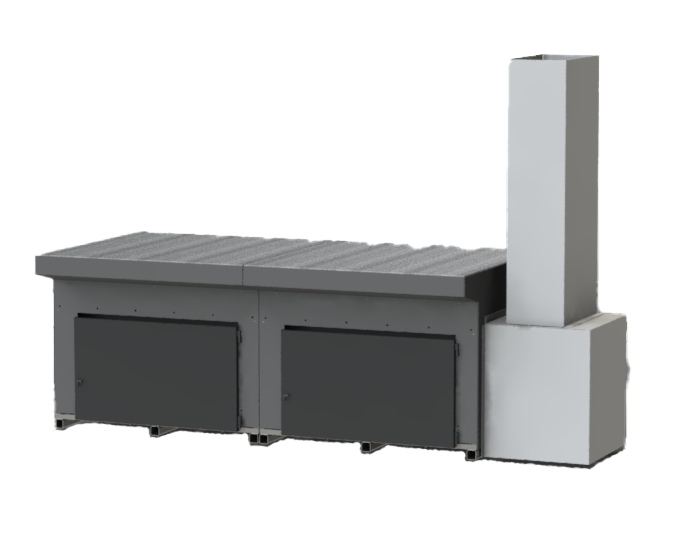

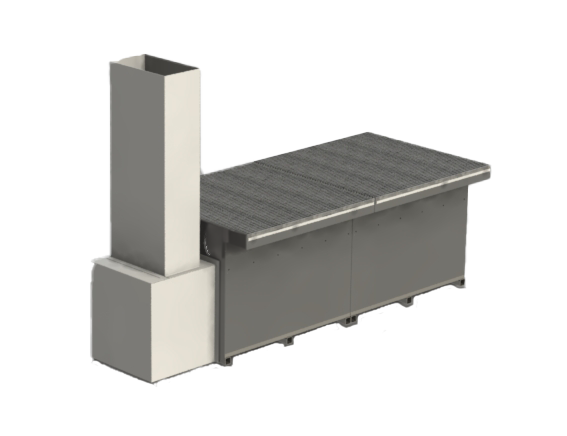

Ensure a clean and safe workspace for welding and grinding operations with the Eliminator Industrial Downdraft Table Series by Go2Industrial. Equipped with a powerful downdraft ventilation system and evenly distributed airflow that effectively captures and contains fumes, smoke, and non-combustible dust particles at the source, before they can enter your breathing zone.

Optional features include side and back walls, task lighting, noise reduction systems, and a built-in sensor that lets you know when it’s time to replace your filters. We can also integrate additional accessories like tool hangers and storage drawers to enhance functionality and efficiency.

Applications

- Welding

- Soldering

- Deburring

- Grinding1

- Sanding1

1For non-combustible, non-explosive dust only

Product Features

- Capture airborne contaminants at source

- Available in 4×4, 4×6, and 4×8 configurations

- High quality filtration

- Fully compliant with OSHA guidelines

- Robust construction

- Versatility and flexibility

- Service indicator for easy maintenance (optional)

Technical Specifications

| Product Number | CFM | FPM | Volts/Phase/Hz | Motor (HP) | Net Weight | Width | Height | Depth | Standard Filter |

|---|---|---|---|---|---|---|---|---|---|

| G2I-DDT-4x4 | 4000 | 360 | 220,460,575V/3/60Hz | 5 HP | 610 lbs (277 kg) |

68" | 48" | 38" | Fire Retardant Nanofiber MERV 15 |

| G2I-DDT-4x6 | 5000 | 340 | 220,460,575V/3/60Hz | 7.5 HP | 720 lbs (327 kg) |

92" | 48" | 38" | Fire Retardant Nanofiber MERV 15 |

| G2I-DDT-4x8 | 6300 | 320 | 220,460,575V/3/60Hz | 10 HP | 860 lbs (327 kg) |

116" | 48" | 38" | Fire Retardant Nanofiber MERV 15 |

What is a downdraft table?

A downdraft table is a type of workbench with a built-in ventilation system that pulls contaminants such as dust, fumes, and smoke away from the work area and into a filtration system, providing a cleaner and safer work environment.

How does a downdraft table work?

Downdraft tables use fans to create a downward airflow through the perforated surface of the table. This airflow draws particulates away from the work surface and into a filtration system where contaminants are captured before the air is either recirculated back into the room or exhausted outside.

What are the benefits of using a downdraft table?

- Improved air quality: Reduces the presence of dust, fumes, and other airborne contaminants.

- Enhanced worker safety: Minimizes exposure to hazardous materials.

- Cleaner workspace: Keeps the work area free of debris and particulates.

- Compliance with regulations: Helps meet workplace safety and environmental standards.

How do I maintain a downdraft table?

- Regular cleaning: Keep the surface and filtration system clean to maintain optimal airflow.

- Filter replacement: Replace filters according to the manufacturer’s recommendations or when they become clogged.

- Inspections: Regularly inspect the table for any wear and tear or damage that could affect performance.

How do downdraft tables compare to other ventilation systems?

Downdraft tables offer localized ventilation directly at the source of contamination, which can be more effective than general room ventilation systems. They are particularly beneficial for tasks that generate significant amounts of dust or fumes.

Can downdraft tables be customized?

Yes, at Go2Industrial, we offer customization options to fit specific needs, such as different sizes, filtration systems, and additional features like back and side walls, hoods, integrated lighting, or tool storage. Contact us today to learn more.